Connect real-world field devices over Ethernet and know the status of your mission critical processes at any time

Building an effective system for fermenting beer can be challenging, especially when it comes to monitoring and controlling the temperature of fermentation vessels. Breweries are eager to find a way to constantly measure the temperature to ensure that it stays in a narrow range. In this case, for heating and cooling down the temperature of the beer at appropriate intervals.

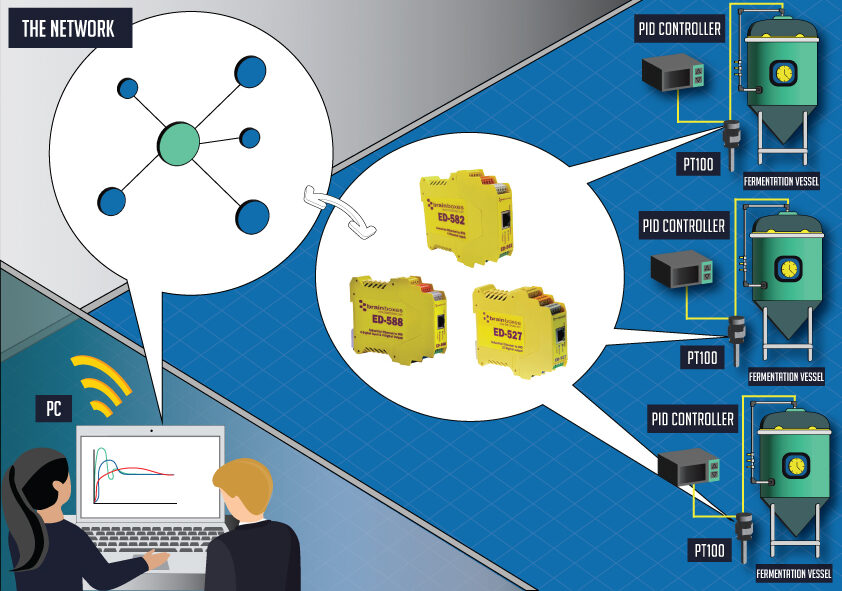

PT100 temperature sensors are a cost-effective way of measuring temperature and can work in conjunction with the PID controllers, which can be wired up to the PT100 sensors inside multiple fermentation vessels. The PID controllers can then be adjusted to alter the temperature of the vessels from their central location.

The above system has the ability to keep the temperature at an optimum range, but it lacks a beneficial remote-control option. Ensuring repeatable accuracy of temperature sensing can be difficult due to variations in the measurement chain. The current system requires users to physically attend to the vessel to retrieve data and manually record the temperature. This process increases the chance of data errors and corporations increasingly want to connect their data together.

Using Brainboxes Remote IO devices, users can monitor inputs and control outputs from any location. The Brainbox can connect to sensors in different locations within the vessel to ensure data reflects the average temperature across the whole vessel.

The temperature of beer has a tendency to stay constant overtime, but accurate and precise measurements are critical to maintain the quality of beer. Open/short detection on the temperature IO Brainbox (ED-582) detects any errors and sends an alert to the PC, such as a break in the circuit. This enables the user to monitor any errors to ensure that all of the channels in the circuits are efficient.

The ED-582 works collaboratively with Digital Output Brainboxes (ED-588 and ED-527) to control the temperature of the vessels: creating an effective system where the vessels can be controlled from any location. There is no need for any human involvement because the Brainboxes work together with the PT100 sensors to gather measurable data from the environment, enabling the user to maintain inputs and control outputs automatically from any web browser.

Brainboxes Remote IO devices allow you to retrieve data from your machines and integrate it with other data from around the organization. Using Brainboxes devices, breweries can extend the reach of temperature monitoring and control securely across their entire company network.

-

ED-527

$280.67 Add to cart -

ED-582

$408.38 Add to cart -

ED-588

$280.67 Add to cart