How the internet of things will affect our future

Luke Walsh – “In 2016 I gave a presentation at Liverpool’s John Moores Universityi. I was talking to the next generation of engineers about what their jobs might look like and trends which are going to shape the way engineering evolves as industry moves forward into this 4th

revolution. The tone of my original talk was quite light and fun, but there are some serious and business critical implications behind the conclusions that warrant discussing further.”

IoT, the Internet of Things is a buzzword that has been bandied about for some time. In the last year it was one of those phrases that was slapped on just about everything, whether or not it was really relevant. I think we all realise that it will be important and that we should be working

towards IoT, but there is still a lot of confusion about what it really means and how it works in practice. What is our IoT world really going to look like?

Let’s imagine the good, the bad and the unfortunate for a minute:

You start the day gently awoken at 7:29am by your Sleep monitoring Garmin smart watch which detects your circadian cycle and wakes you knowing the time you wish to rise and your optimal sleep requirement.

You go into the bathroom and stand on your Withings weighing scales which shares data with Tesco. It changes your next shopping order to low sugar biscuits. But you are doing well with your tooth brush, its sent you a voucher for a free clean and polish as a reward for brushing three times daily for the last month.

You drive to work in your Tesla self-drive electric car which communicates with Microsoft office assistant to reschedule a morning meeting because the car has detected slow moving traffic ahead.

At work – the machines on the production line advise you that a motor is about to fail, but not to worry an advance replacement is automatically on the way from RS Components.

Your watch buzzed at mid-day to remind you that you had set a goal this week to walk half an hour at lunch time each day. This will help reduce your life insurance premium automatically if you continue with this for 6 months.

Back at work in the afternoon your production monitoring also informs you that when Bob is running the night shift you have more productive periods than when Jim is in charge.

Maybe it’s time to fire Jim? the government has a feed on your data and therefore already knows you’re considering this, and has pre-emptively mailed Jim with recruitment advice.

Half an hour from home your car notifies your NEST thermostat that you are on the way so it puts the heating on. You step out of our car and it automatically opens the garage, parks itself and charges the battery when electricity is cheapest by communicating with the national grid.

Your bathroom scales added healthy fish to your menu so whilst cooking dinner you change the level of room fragrance using the Febreeze IOT app on your phone. However, the scales haven’t overridden your order of beer and wine and your IoT fridge has snitched on you to your health provider. They have dispatched a test kit for liver health – maybe you won’t get that insurance discount after all.

Is this really the future of the Internet of Things?

In this imagined ‘day in the life of’ we are using a fairly broad definition of the internet of things; any device that can connect out to the internet and can monitor and/or control something. For instance, Google Nest is an example of something already on the market that fits this definition of IoT. It connects via Wi-Fi to sensors monitoring temperature and can send a command to the heating system to adjust the radiators. So, the signals, the communication, is over the internet but the control and outcome is a real world ‘thing’ (not virtual). Of course, the utopian scenario is that this automation enhances our lives, but there are some legitimate concerns and some seemingly bizarre potential repercussions.

It takes a while for any new technology to find its way in to our day to day lives, for the kinks and bugs to be worked out and to get to the real usefulness of it. Until we get to a certain point, with enough IoT applications deployed to get real data, we are speculating about the potential impact, both the positive and negative.

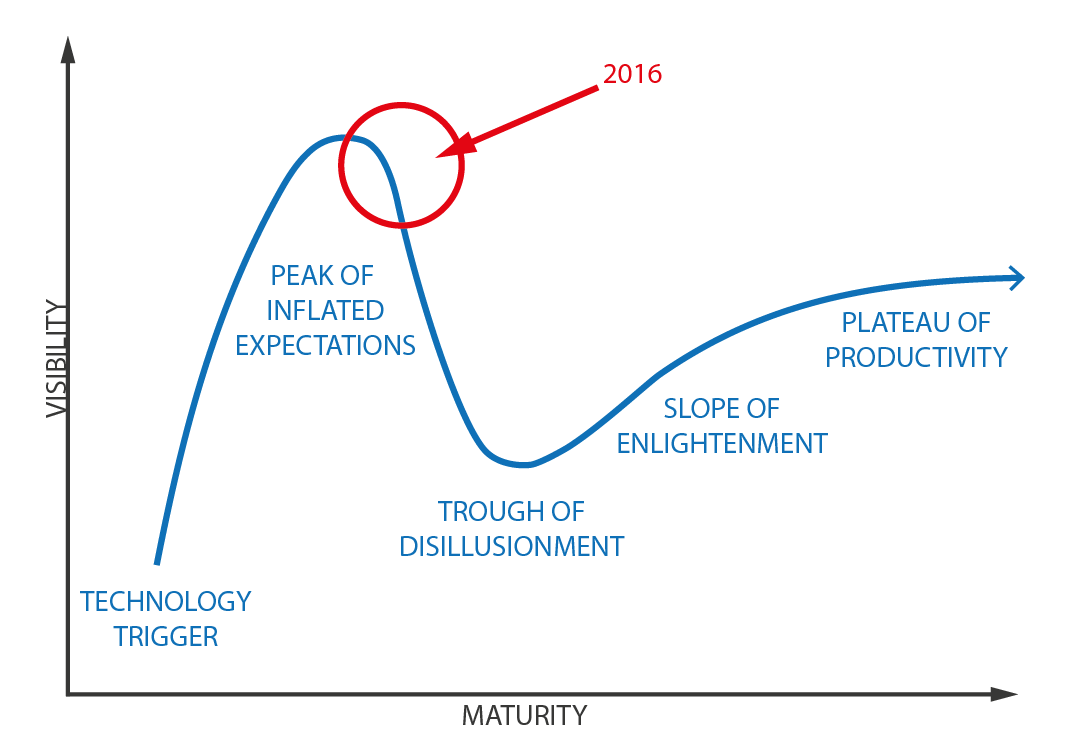

Gartner Hype Cycle

Gartner Hype Cycle

So, in the Gartner hype cycle1 we are somewhere between the peak of inflated expectation and heading for the tough of disillusionment. Having embraced smartphone technology most people are receptive to add-ons that they can control from their phones, but not every product on the market is going beyond the novelty factor to add real value to our lives. For the traditionally conservative industrial market there is still much scepticism that the benefits of IoT will outweigh issues of set up cost or security. But that is changing as engineers realise the enormous potential of IoT for industry. Gartner’s much publicised prediction is that the number of things connected “will reach 20.8 billion by 2020”. They also predicted that whilst the majority of connected ‘things’ will be on the consumer side, that more money will be spent by enterprise or business.

The industrial internet of things and the term Industry 4.0 or the 4th industrial revolution, are often used interchangeably. More accurately Industry 4.0 encompasses IoT, but also goes beyond to describe a broader integrated and optimised approach to manufacturing. As such Industry

4.0 is strongly connected to big data, which will be supplied in no small part by internet enabled things. The development of the processing power and storage needed to manage large scale data has been an important step towards enabling the next generation of commercial IoT applications. But it doesn’t have to be big data, most IoT applications start with ‘small data’. It could be as simple as measuring up time on a machine to infer its power usage.

To update an old cliché, data is power. In tough economic times businesses can’t afford to waste money and must make expenditure decisions based on real information rather than anecdotal evidence. Of course, the production line, born as it was from a need for increased efficiency and

productivity has been subject to numerous improvements over the years. Lean manufacturing, the Toyota way, six sigma and the like all start with measuring processes in order to identify waste. The larger and more complex the production set up gets, the more diverse and numerous sources and points of waste become. It is amazing how a few mis-timed seconds in one part of a factory can cause major disruption down the line and thus cost the business. But how much does it cost? Enough to make a change? Change what?

We may be dealing with an age-old problem but the cost and availability of the technology to solve it has changed dramatically and it’s one of the ways IoT will contribute to Industry 4.0.

IoT combined with big data doesn’t just enable us to make sense of large amounts of data it can also put it into context and combined with the right applications presents insight that can lead to significant cost saving.

It is at this application stage that engineers will see the biggest shift in their profession, with a merging of mechatronics, software and network IT skills. With hindsight, we might look back and say of course the Internet of Things meant the integration of internet and thing, the hands on and the virtual, blue and white collar, but we are currently just beginning to realise how the skills profile of our workforce will need to develop. We have software engineers who program and can visualise what to do with data, but don’t necessarily know how to get at that data, what needs physically wiring in. Then we have engineers who understand the equipment and can install the hardware to get the signals out of the machines, but lack the ability to get that data into a useful format or presentable for management. Bridging the gap between the levels of data will form a key part of the Industry 4.0 transition.

So IoT is offering a way to see our production lines. Data is already there, being generated by machines already installed. At level one we have raw signals generated by our machines, on/off, high/low. The second level assigns a value to each state, e.g. if the fan and light are on the machine is running. At the third level of data we start to make it useful to us and we are generating some statistics, such as, if we record the time the machine is running we can report the uptime across a shift. At the fourth level, we are monitoring uptime over time and getting to insights that enable improvements.

If we think back to our imaginary IoT day and poor Jim who we were about to fire. Looking at our integrated data we can see on Jim’s shift more essential maintenance was performed, decreasing his output, but reducing breakdowns for the following shifts. Overall Jim is contributing a better performance than Bob.

Obviously, there could be many reasons why maintenance is happening on Jim’s shift but not on Bob’s and it is critical we don’t jump to conclusions. Our handling of data will need to become increasingly sophisticated. Particularly as we unlock large amounts of information and

bombard ourselves with statistics it will be challenging to make the right interpretations.

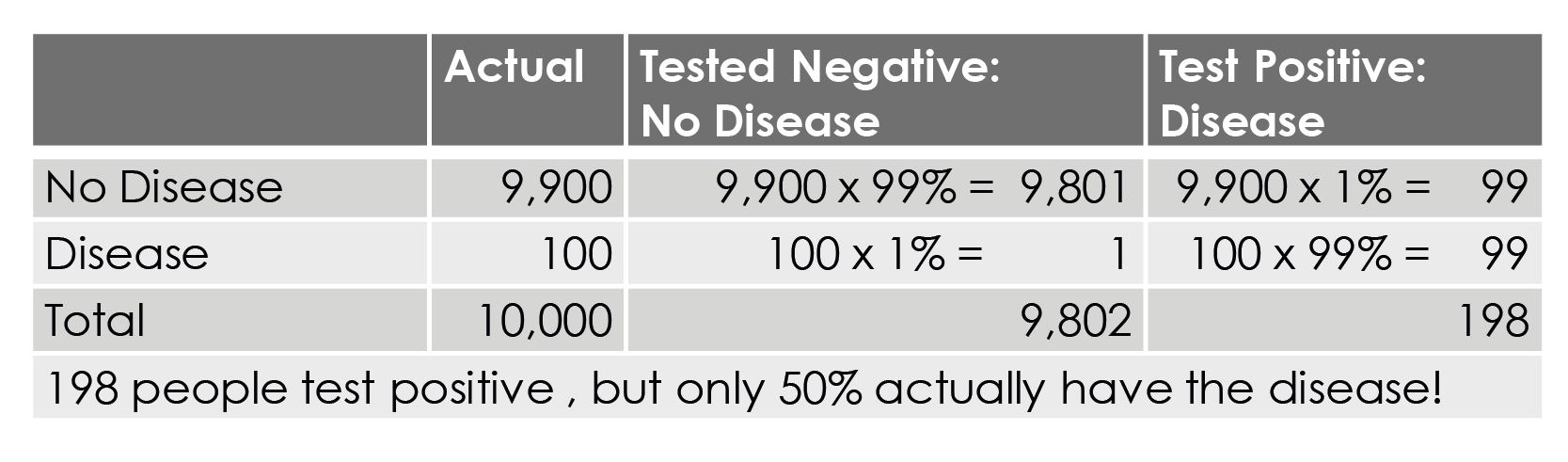

An example I gave to the students was about a drug which diagnoses a disease accurately 99% of the time. However, in a population where only 1% of the people have the disease, the 1% false positive actually results in an 20% misdiagnosis. Work through the maths and you’ll see something which sounds acceptable at first would be disastrous in real life. Another famous example is the case of the missing bullet holes2. The story goes when planes returned to base in WW2 the engineers would look at where the bullet holes were and reinforce those parts of the aircraft. It wasn’t until someone realised it was the planes that didn’t make it home that had the holes they really needed to see that they could make the right improvement.

These examples show how we need to ask the right questions and understand the response we get. What we haven’t yet reached with the Internet of Things and what might be some way off, is leaving the response to that top level of insight to an automated system. Ultimately, we shouldn’t feel removed from our systems but more connected to them. In the best scenarios, the interface, the application and the hardware work together so that they and not you are the invisible part. We may never want to relinquish decision making control; it is important that IoT and Industry 4.0 work for us at the level we want.

The comedy illustration for the downside of autonomous IoT systems is the hacked fridge. Whilst the image of hackers sat in dark basements trying to disrupt our Ocado order or that out white goods will be in cahoots with a nanny state over our beverage consumption is amusing, but if you substitute fridge for mission critical piece of equipment it becomes an industrial nightmare.

One of the most frequent concerns we hear is security. Amazon’s Echo ordering from your TV’s adverts is inconvenient, the idea your conversations or private data are visible to third parties is a corporate disaster. At one point Windows 10 automatically shared your Wi-Fi passwords with your contacts3. Samsung issued a press release in 2016 asking their customers not to have private conversations in front of their Samsung Smart TVs4. A feature that was conceived as an enhancement to make life easier is in practice clearly an undesirable security risk.

But security has always been an issue. For companies large and small, in the virtual and real world there are countless examples where we have got it wrong. (Check out human hacker Jenny Radcliffe talking about how she breaks into banks for a livingi). Naturally with the internet our errors and breaches can be on a global scale which brings an understandable level of caution.

Thus, we need to think carefully about what needs to be IoT enabled, remembering true IoT is more than just networked equipment, but layers of automation and autonomy. What permissions and privacy do we need? Who are we trusting to deliver this IoT data to us? For the majority of companies an in-house custom solution will be prohibitively expensive, leaving most of us to rely on third parties and off the shelf offerings. Using IoT systems may carry the possibility of cyber-attack just as we may lock our doors and still get burgled. We take reasonable precautions relative to what we are protecting and the same common sense should apply to network or cloud security. However, In the physical world when there is a robbery, the liability is reasonably clear: we have insurance to cover us against damage and loss. In the virtual world who is at fault? The device manufacturer? The operating system vendor? The cloud provider? Should we insure against any breaches? Should we disclose breaches? Do our customers have a right to know if their data has been comprised? Should we insure against breach? Who with?

It is up to engineers to collaborate with software developers, system administrators and network architects to mitigate the risks and start designing the infrastructure of tomorrows IoT world today.

1Van der Meulen, R. (2015). Gartner Says 6.4 Billion Connected “Things” Will Be in Use in 2016, Up 30 Percent From 2015. Available: http://www.gartner.com/newsroom/id/3165317. Last accessed 10th January 2017.

2Ellenberg, J. (2014). How not to be wrong. Available: http://www.rigb.org/blog/2014/june/how-not-to-be-wrong. Last accessed 10th January 2017.

3Winder, D. (2015). Windows 10: Wi-Fi Sense makes no security sense at all. Available: http://www.itpro.co.uk/security/25048/windows-10-wi-fi-sense-makes-no-security-sense-at-all. Last accessed 10th January 2017.

4De Souza, R. (2016). Be careful of what you say in front our Smart TV, warns Samsung. Available: https://www.hackread.com/samsung-smart-tv-listening-conversations/. Last accessed 10th January 2017.

Greenberg, A. (2015). Hackers remotely kill a jeep on the highway – with me in it. Available: https://www.wired.com/2015/07/hackers-remotely-kill-jeep-highway. Last accessed 10th January 2017.

Mathews, L. (2013). Smart toilet security flaw could leave you with a soggy bottom. Available: http://www.geek.com/android/smart-toilet-security-flaw-could-leave-you-with-a-soggy-bottom-1564411/. Last accessed 10th January 2017.

Ross, E. (2016). Baby monitors ‘hacked’: Parents warned to be vigilant after voices heard coming from speakers. Available: http://www.independent.co.uk/life-style/gadgets-and-tech/news/baby-monitors-hacked-parents-warned-to-be-vigilant-after-voices-heard-coming-from-speakers-a6843346.html. Last accessed 10th January 2017.

iWatch the original talk: https://youtu.be/c4C89L4hiK0

iiPeople hacking: https://youtu.be/-j6Y0U0e240