“The best machine in the world is nothing without a skilled operator. The right digital tools will help the engineer get the best out of the machine” – Oliver Miller, Industry 4.0 Project Manager at Beverston Engineering

The digital improvement journey aims to increase value for businesses by automating the manual process. Digitisation is especially beneficial for understanding the status of your mission critical processes at any time.

Beverston Engineering are a manufacturer specialising in safety critical, precision parts for aerospace, oil and gas, and pharmaceutical industries. Quality and continuous improvement are paramount to their process, rather than mass production. Their pursuit towards quality is recognised in their commitment to producing mission critical parts where failure is not an option. Industry 4.0 project manager, Oliver Miller, aimed to further implement quality 4.0 practices through the digital improvement project.

Before the project began, the majority of Beverston’s data collection was manual or paper-based. Engineers had to manually collect the data from individual machines, but Beverston aimed to find a way to accumulate all of the data rather than siloed data. However, the digital improvement project was not without its challenges since it required the digital skills of engineers to make it a success.

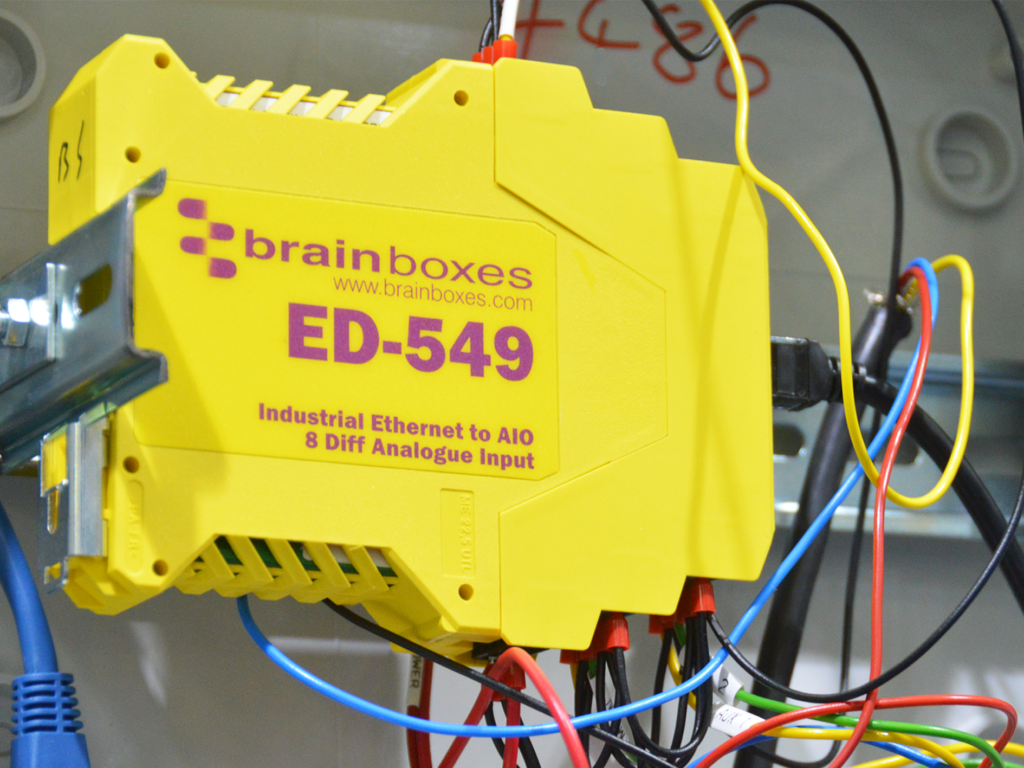

Fortunately, Brainboxes Remote IO devices makes the digitisation process easier by automating the collection of data. Brainboxes were chosen to assist with the digital improvement project due to the scalability of the products. For instance, the remote capabilities of the Ethernet to Analog inputs Brainbox (ED-549) allows you to view data from anywhere in the world.

Beverston Engineering use air compressors to drive their machines. However, in the absence of automated data collection, engineers were unaware of the status of the back-up compressor systems. By integrating Brainboxes ED-549 into their digital improvement project, they could determine the compressor status. The ED-549 measures the current of the main and back-up compressors and is wired to a sensor generating analog inputs. The ED-549 allows you to take real-world signals and turns them into data on your network. In this case, the data measured detected whether the compressors were on or off. By monitoring the data, Beverston discovered that their machines had been running for 9 months on the back-up compressor, rather than the main compressor.

With the ED-549 working in conjunction with Datahone’s data capture system; Datahone alerts engineers via text or email concerning the power-usage of the compressors. This process also informs the engineers when the back-up compressor has automatically turned on when the main compressor is faulty.

“We were running on the back-up compressor for a long period of time and didn’t realise” – Oliver Miller, Industry 4.0 Project Manager at Beverston Engineering

To continue facilitating quality measurement, Beverston were eager to understand how their machinery could be affected by temperature changes. The company were also eager to capture the energy usage of their machines.

To measure temperature and energy usage, they used two current clamp temperature sensors to measure the electric current flowing through the wire. The current clamp is fitted onto a high voltage panel board to measure the total energy of the whole building. The sensors are wired into the ED-549 which detects an increase in the voltage of the sensors output signal. The sensor detects changes in the supply current which then is converted into a readable low voltage signal from the ED-549 via analog outputs. The Datahone system then collects the measurements from the ED-549 and the data is sent to a central monitor for visualisation. The monitor provides the entire factory floor with an instant view of live and historical data. The data is comprised of the compressor status, the temperature and power status of the entire factory.

This process provided Beverston with a system where they could track the temperature to see if they are at risk of quality failures. For instance, they could see if the factory floor needed additional ventilation. The data also helped them to recognise the money that they could save if they invested in a cooling system. If the quality of the products was affected by the temperature, they could justify the investment of a cooling system with hard data.

This process also provided them with visual data of energy usage which helped them to recognise when the machines were running. Due to the insights from the automated data, Beverston discovered that they were using more energy at the weekend than they had previously thought. This was due to certain machines that had been left on and were consuming energy. The engineers could then switch the individual machine off from the electrical distribution board to save on energy costs. Utilising this approach corresponded to an energy saving cost over the year of several thousand pounds.

By using the Brainboxes ED-549, Beverston achieved their goal of eliminating manual data collection and analysis. This is due to the ED-549’s high precision measurements of voltages and currents. Engineers no longer have to rely on reading the measurements from a voltmeter, instead the ED-549 integrates with Datahone to produce visual data. Monitoring the data led to reduced energy consumption and elimination of compressor unplanned downtime for Beverston Engineering.

-

ED-549

$408.38 Add to cart