Make the most of your production line

Production lines often fail to reach their maximum capacity – can you afford to ignore your potential?

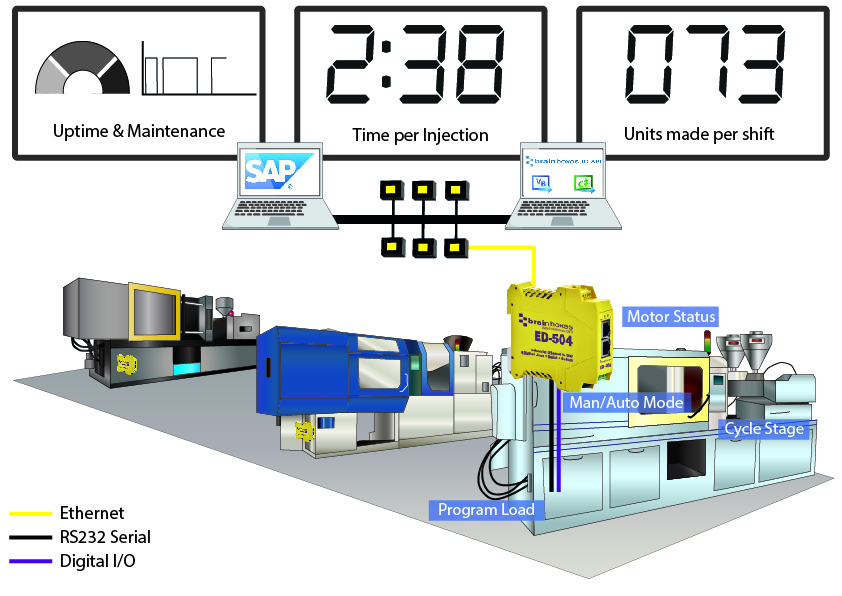

Select a future proof solution that will allow system expansion whilst connecting all those reliable but decades old machines.

There are tons of signals produced by factory equipment, but its finding the ones which are important and can provide beneficial insight that is the starting point for industry 4.0. How we get from an electrical circuit, to a productivity report, to an intelligent flexible process starts with getting the right connection. That’s why brainboxes devices offer multiple ways to unlock the signals from your machines and get them into a useful state.

The benefit of control, monitoring and automation for factories and plants is the improvement of efficiency, often measured as OEE (Overall Equipment Effectiveness) can maximise production and minimise hidden costs such as down time, making factories more profitable.

An option is to use our API library to write your own software. API stands for application programming interface, which, as the name suggests, offers an interface between a device and the programming language you are familiar with. For example we offer C#, Python, Perl, and

Visual basic to name a few. APIs make life easier for software developers enabling them to get applications up and running faster.

However, if you want something specific, but don’t know how to go about it, we can help write the software for you and provide custom control and monitoring solutions that display the information and insight that’s important to you.

Our staff are always happy to chat, so if you have any questions please get in touch.